- Call Us: +91 7719809884

- Email: sales@winspect.co.in

Solutions

Training & Development Services

Winspect Infosystem also provides training & development service on Cadence-OrCAD & Allegro Electronics Design Automation Too for industry & education segment, our training faculties have wide range of industrial experiences.

Engineers and Diploma Holders in Electronics can get world class training on Cadence-OrCAD & Allegro tool. Course curriculum is designed to meet the needs of a wide variety of Electronic design companies. The participants receives comprehensive, world class reference guide on OrCAD & Allegro, with the workbook. Electronic Engineers with working knowledge of OrCAD & Allegro (Simulation & PCB) tool have a high employability in India and abroad as many MNC electronic design firms have established their design centres in India; hence demand for trained electronic engineers is increasing rapidly.

Pneumatic Solutions

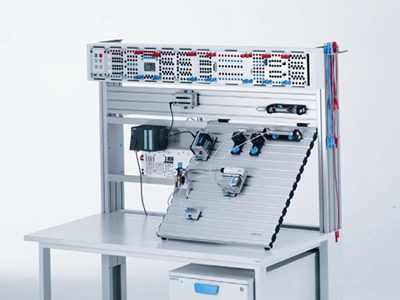

Training system for automation and technology is geared towards various educational backgrounds and vocational requirements. The training packages are therefore broken down as follows:

- Basic modules impart basic, interdisciplinary, technological knowledge.

- Technology modules address the important topics of open and closed-loop control technology.

- Function modules explain the fundamental functions of automated systems.

- Application modules enable training and further education that is aligned with real-life practice.

The technology modules deal with various technologies including pneumatics, electro-pneumatics, programmable logic control systems, automation using a personal computer, hydraulics, electro hydraulics, proportional hydraulics, sensor technology, electric drives and applications technology (handling).

Hydraulic Solutions

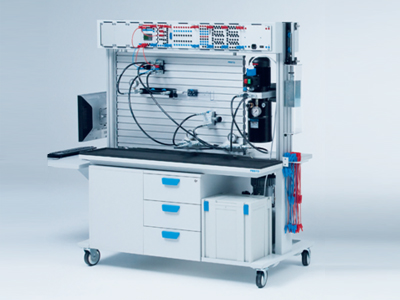

Hydraulic learning system for automation and technology is geared towards various educational backgrounds and vocational requirements. Correspondingly, the training system is broken down as follows:

- Technology oriented training packages

- Mechatronics and factory automation

- Process automation and control technology

- Mobile robotics

- Hybrid learning factories

The training system for automation and technology is continuously updated and expanded in accordance with developments in the field of education, as well as actual professional practice. The technology packages deal with various technologies including pneumatics, electro-pneumatics, hydraulics, electro-hydraulics, proportional hydraulics, programmable logic controllers, sensor technology, electrical engineering, electronics and electric drives.

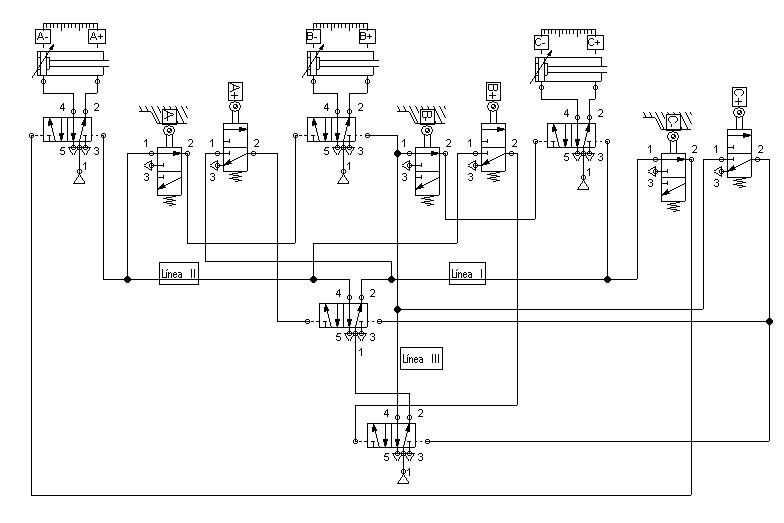

Hydraulic and Pneumatic Circuit Simulation Software

As a teacher and trainer, you are the expert who masters tasks that are needed to prepare lessons. That is why Circuit simulation software offers the expert mode. Your trainees should initially concentrate on the essentials. They can work and learn successfully in the standard mode, which has a reduced range of functions and offers advantages for the learning process. Whether in a training environment or in an engineering office, the simulation of control systems and processes has been standard in industry for a long time; it helps to minimise losses due to crashes and ensures greater efficiency and improved quality. The new simulation core of FluidSIM® 5 achieves simulation rates up to 10 kHz. The parameters of all actuators can be precisely adjusted. FluidSIM® 5 writes the simulation results in millisecond cycles and delivers them as a text file! The new simulated oscilloscopes make frequencies up to 100 kHz visible.

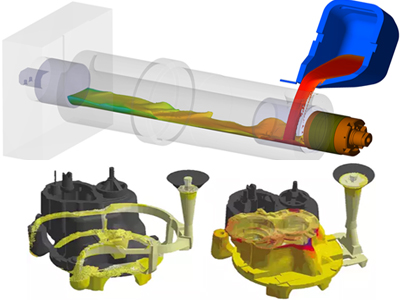

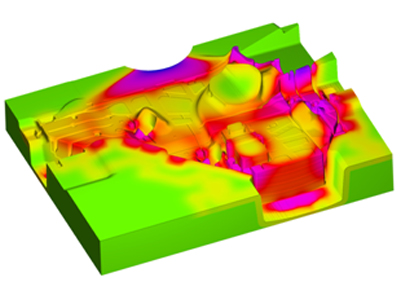

Casting Simulation Software

Casting Simulation Suite, provides a complete set of solutions for the foundry industry. As the manager of a foundry, your major concerns revolve around productivity and quality minimizing rejections while maximizing melt utilization and saleable output. You have discovered repeatedly that the conventional manual method is tedious and seldom helps you reach an acceptable mould design consistently. Very often, you pour more melt than is necessary, then adopt a trial and error approach that produces something that is barely acceptable – resulting in poor yield, wasted time, effort and resources.

Casting Simulation suite has the answer to those methoding nightmares. It’s a state of-the-art simulation and methoding system that is easy to use, helps you cut down on method design time, while producing quality castings.

Automatic Test Equipment

Automatic Test Equipment will have all the equipment necessary to enable the rapid test and fault finding of Units to enable rapid turn-around-times for quick replacement & continued operation of the host units.

The solution proposed will consist of:

- Functional tester to test LRUs and identify the Pass/Fail.

- Modular Diagnostic sub system to test LRUs and identify the faulty components.

An easy-to-use scalable turnkey solution for the functional & diagnostics test of your LRUs, PCBs and electronic assemblies.

The Functional tester is customized to test the Line Replaceable Unit (LRU) to determine the faulty LLRUs.

Automation Solution

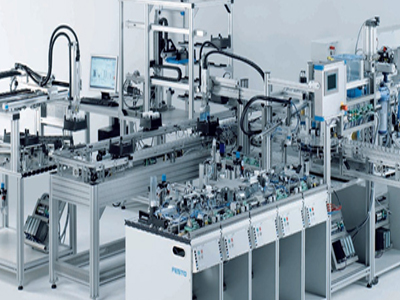

The Automation system fits in a cabinet but can also be combined to create networked production lines.

The Automation systems are supplied with trolleys, provide space for the control system, are fully assembled and can be a basis for complex learning factories.

Practical at every level

The modular production system sets the right challenges and provides appropriate learning environments for various requirements:

- Differentiated functions

- Individual and combined units

- Different drive technologies

- Material and information flow

- Modern and variable control concepts